-

Solution

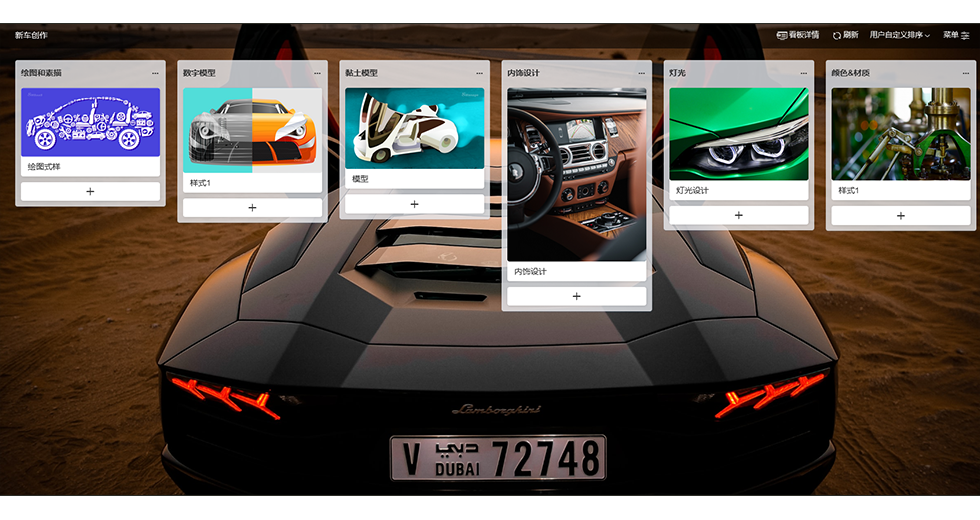

8Manage Kanban is a scheduling system that tells you what to produce, when to produce it, and how much to produce. 8Manage Kanban provides you with a visual board and allows you to use a card with diagrams and instructions on it to schedule and track different stages in production such as “To Do”, “Doing“ and “Done“.

Kanban can be used for different types of situations such as:

- Printer production

- Car manufacturing

- Software development

- System implementation

- Video game development

- Animation production

- Event marketing

- Sales automation

- Service desk

- Sourcing

- Purchasing

- Just-in-time inventory

- Logistics management

- Recruitment

- Training program

- Corporate social responsibility

- Merger and acquisition

8Manage Kanban can be applied across all fields of work to help teams drive down costs and become more efficient by visualizing and improving workflows. 8Manage Kanban gives you the flexibility to build sustainable a competitive advantage and empower your team to accomplish more and faster. Visualization is the most important Kanban practice. Every project has a backlog of activities (To Do) to get through, and a series of process states (Doing) that an activity must pass through before it is delivered (Done). Using thegives you the flexibility to build a sustainable competitive advantage and empower your team to accomplish more and faster. Visualization is the most important Kanban practice. Every project has a backlog of activities (To Do) to get through, and a series of processes states (Doing) that an activity must pass through before it is delivered (Done). Using the 8Manage Kanban board, everyone can instantly see how activities are moving through the process. The simplicity of its visual presentation enables you to easily spot bottlenecks while they are forming.

Traditional management methods rely on planning upfront and pushing the work onto the teams. This results in teams often struggling with more work than they have the bandwidth for. 8Manage Kanban employs the pull system – the team pulls tasks into the workflow only when they have the capacity to do so. 8Manage Kanban is imposing work in progress (WIP) limits on each process state. When the WIP limit is reached, no new activities are allowed to enter that state until another activity has left. The WIP limits prevent teams from working on too many activities at the same time and minimize team members’ wasted time on context switching.

An organization’s desire for operational efficiency is prompted by a need for adaptability. 8Manage Kanban’s low code and versatility enable prompt adoption by the different teams and allow them to claim timely victory.