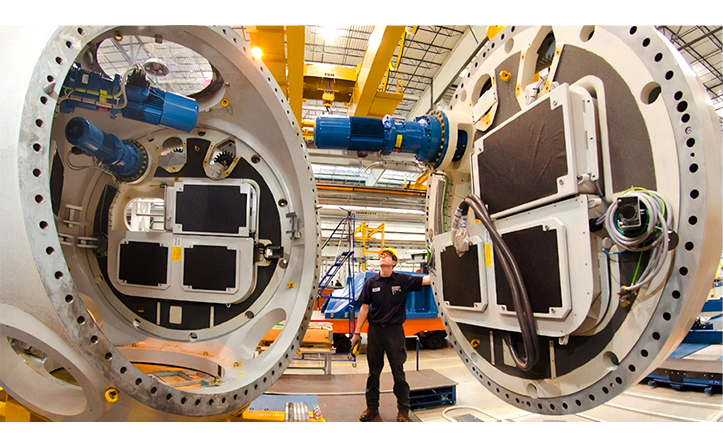

Challenge

Project-based manufacturing, also known as Engineering To Order (ETO), is a manufacturing operation to create a similar man-made product process that can be managed as a project with low inventory levels. It is a special way of manufacturing in the industry. In ETOs manufacturing, every product created is the end result of the project. The final product is created in a manufacturing environment where customers and engineers may require engineering designs and specifications. Therefore, in an ETO environment, customer needs are unique and sometimes complex. It is part of a combination of engineering and manufacturing processes. Producing a product is only one component of project manufacturing, and many of the processes that should be done need to be integrated for better planning and control of the manufacturing project business.

In project-based manufacturing, the methods used are not suitable for high-volume production planning and control applications to make the item because the final product requires uniquely engineered product design or significant customization. Past research has argued that it is important to have an innovative approach to integrating manufacturing and logistics with project management. The ETO segment includes various types of companies that design and manufacture various products. This enables manufacturers to plan, organize and control projects to produce the final product. ETO companies are usually involved in tendering, product design, manufacturing, installation and contracting. The characteristics of an ETO company can be viewed from the market, products and internal processes. Through integration, design and product development in response to market needs, improvisation of product performance and more affordable prices for customers improves the efficiency of a company’s products.

- Define purchased materials, characteristics of goods and services

- Select suppliers who can provide goods and provide services with favorable prices and quality goods

- Manage all aspects of the procurement step to deliver goods or services at the right time

ETO businesses typically spend close to 60% of their sales on purchasing materials or services, so the importance of purchasing significantly impacts the success or failure of a company’s end product. Today, procurement is regarded as a core competency, and many companies place it in a strategically important position. A company’s competitive strategy allows it to determine the performance of operating decisions that lead to preferences. To gain a competitive advantage, the manufacturing strategy must align with the company’s competitive strategy.

Procurement integration may require not only the application of key procurement practices but also aspects such as supplier development, supplier certification or supply base reduction. It focuses on internal orientation and is designed to align with companies with competing priorities in purchasing practices. The manufacturing and corporate strategy of the procurement integration discussion is divided into several conceptual frameworks, one of which is an existing framework study that emphasizes the significance of procurement in formulating and executing business strategies.

Similar to businesses that require project-based procurement, ETO companies also have difficulty finding software for project-based procurement in the market, as it is much more difficult to create software for project-based procurement than for category-based procurement.

Solution

All-in-one supports project-based procurement and production. The system allows you to plan and execute the following in your project:

- Conduct supplier surveys and market research. This includes the identification of potential suppliers and areas of concern at the business category or strategic level

- Start a quick quote, tendering (RFI, RFP, RFQ) or auction process

- Shortlist suppliers and evaluate existing opportunities to reduce costs, improve quality and increase revenue

- Negotiate and award contracts and quality or service level agreements for new suppliers: agree on terms of supply, including the nature of the relationship and its subsequent management within the framework of the project

- Monitor procurement activities of the project: ensure compliance with obligations and any compliance aspects

- Close projects and related contracts and agreements

- Conduct supplier evaluations and performance feedback

Material related activities

- Material library (codes, specifications, inventory, workmanship, lead times...)

- Bill of Materials (BOM)

- Material distribution

- Inventory tracking

- Material release

- Material receipt

- Grouping

- Material distribution

Production Activities

- Project production plan

- Material inspection

- Production progress monitoring

- Quality control

- Exception handling

- Scrap processing

The focus of All-in-one is that it is project-centric, with activities such as supplier management, sourcing management, procurement management, and material management embedded within the project, which is their external context.