Special News

Efficient Large Equipment Procurement in Machinery Manufacturing: Process & Tips

2025-08-07

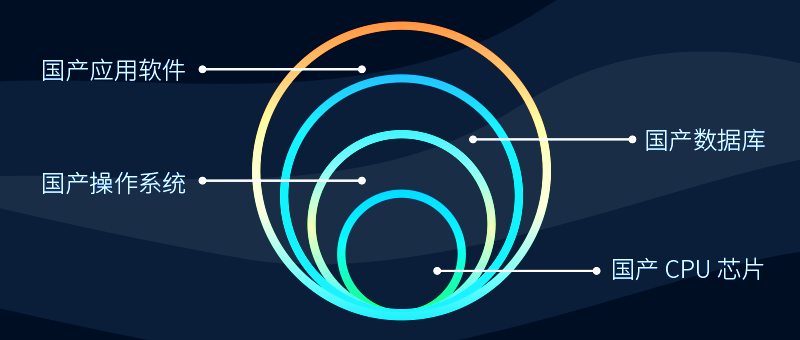

In the machinery manufacturing industry, large equipment procurement is a critical task involving significant capital investment and high technical requirements. A standardized procurement process ensures equipment quality, cost control, and risk mitigation. This article systematically outlines the core procurement process for large equipment, key considerations, and how to enhance efficiency using the 8Manage SRM procurement management system.

1. Core Procurement Process for Large Equipment

1. Needs Analysis and Planning

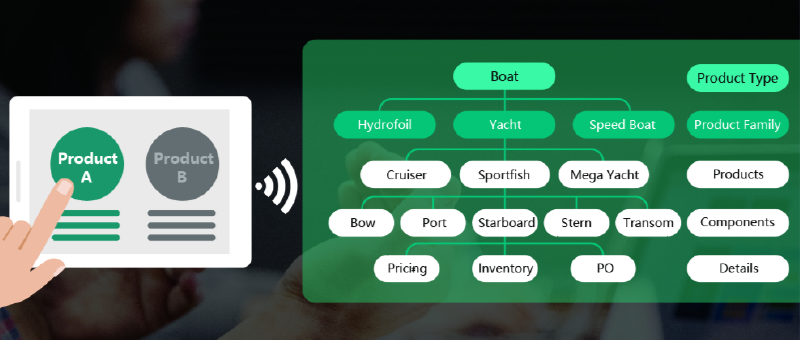

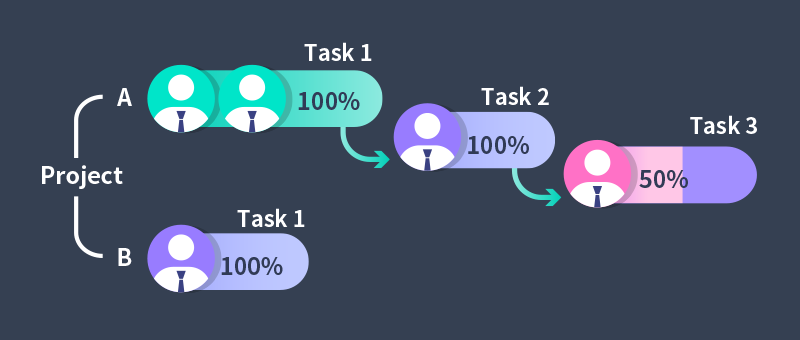

Enterprises must define equipment specifications, performance parameters, and usage requirements based on production goals and technical standards. For example, when procuring CNC machine tools, specific indicators such as machining accuracy and load capacity should be determined. The 8Manage SRM system’s demand management module centralizes departmental requirements, preventing procurement errors caused by information asymmetry.2. Supplier Screening and Evaluation

Supplier qualifications directly impact equipment quality and after-sales service. Enterprises should issue Request for Quotation (RFQ) or tender documents to evaluate suppliers comprehensively based on technical capabilities, delivery timelines, and other criteria. The system’s supplier database automatically assesses credit ratings and historical performance, significantly improving screening efficiency.3. Quotation and Negotiation

Negotiations with suppliers should balance key terms such as price and delivery time. 8Manage SRM supports electronic quotation and online price comparison, with full traceability of negotiation processes, reducing contract dispute risks.4. Contract Signing and Approval

Contracts must clearly specify core terms such as equipment specifications and warranty periods. 8Manage SRM offers electronic contract management with built-in approval workflows, streamlining the process and shortening approval cycles.

5. Equipment Delivery and Acceptance

Acceptance requires strict verification of technical parameters and quality standards. For large equipment, this may involve installation, debugging, and performance testing. The procurement management system tracks shipment status and links acceptance criteria to contract terms, ensuring compliance.6. After-Sales Service and Maintenance

Large equipment procurement should also consider the supplier’s after-sales capabilities, including warranty policies, technical support, and spare parts availability. Long-term supplier relationships help reduce maintenance costs. 8Manage SRM records maintenance history, enabling enterprises to evaluate supplier service quality.2. Key Considerations for Large Equipment Procurement

1. Define Technical Standards and Compliance Requirements

Ensure procured equipment meets industry standards and national regulations, such as ISO certifications and environmental requirements. Close collaboration with technical departments is essential to avoid mismatches in specifications.

2. Control Procurement Costs

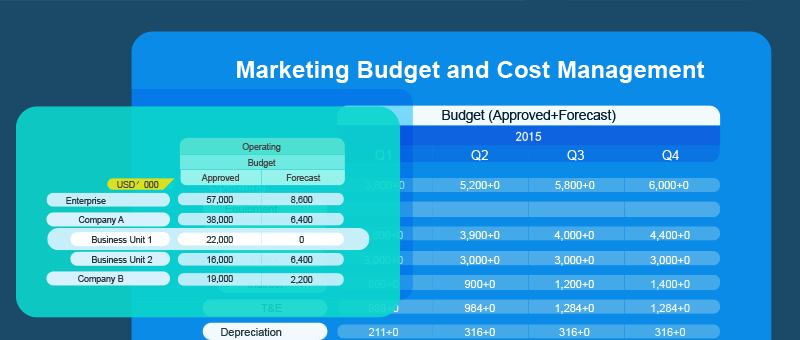

Large equipment procurement involves substantial expenditures. Enterprises can optimize costs through multi-round quotations, supplier competition, and long-term agreements. 8Manage SRM’s cost analysis tools provide real-time budget monitoring.3. Risk Management

Develop contingency plans and include clear penalty clauses in contracts. 8Manage SRM’s risk management feature identifies potential risks and provides alerts for timely mitigation.

4. Cross-Department Collaboration

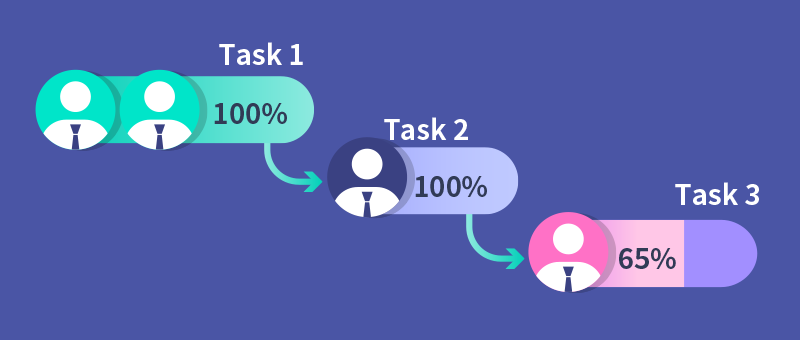

Large equipment procurement often involves multiple departments (e.g., procurement, technical, finance). Poor collaboration can lead to information silos or delays. 8Manage SRM’s integrated workflow management ensures real-time information sharing and improves efficiency.

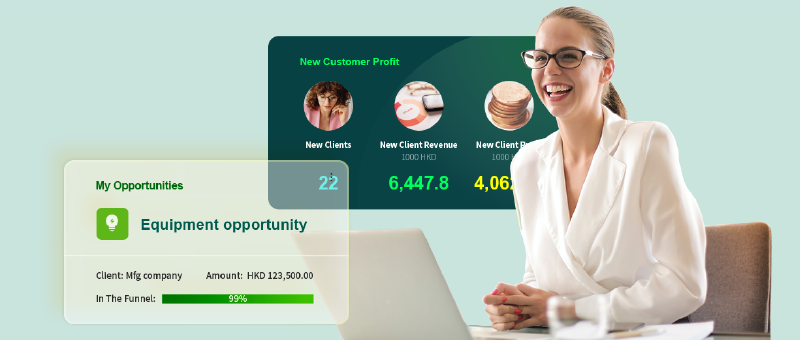

5. Data-Driven Decision Making

Leverage historical procurement data, supplier performance, and market trends to formulate informed strategies. 8Manage SRM’s analytics tools generate procurement reports to optimize decision-making.

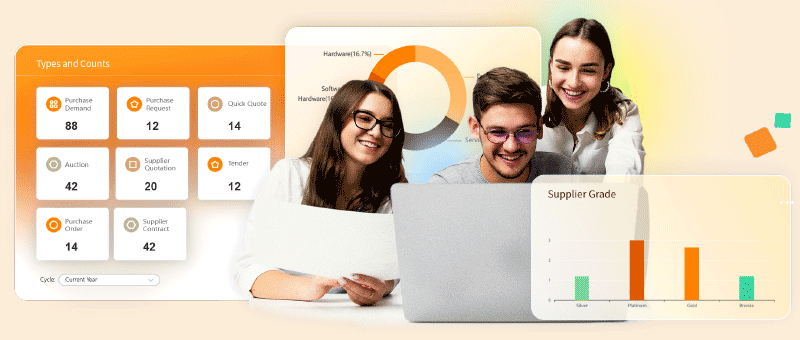

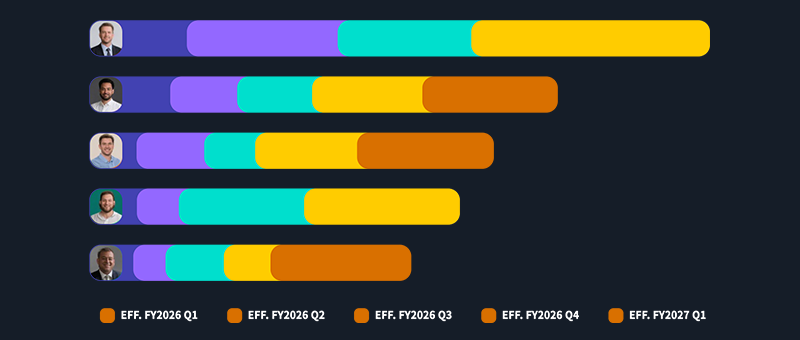

Enhancing Procurement Efficiency with 8Manage SRM

Amid digital transformation, machinery manufacturing enterprises increasingly rely on intelligent procurement management systems. 8Manage SRM, as an integrated solution, covers the entire procurement lifecycle from demand to inventory management. Key advantages include:- End-to-End Automation: Automates quotation, approval, and contract management, reducing manual work.

- Transparent Data: Centralized, real-time data storage for easy access and analysis.

- Modular Flexibility: Supports customizable modules and SaaS deployment, lowering initial and maintenance costs.

- Multi-Platform Support: Enables procurement management via PC and mobile devices.

By adopting 8Manage SRM, enterprises can optimize large equipment procurement and enhance supply chain management, strengthening market competitiveness.

FAQs on Procurement Management in Equipment Manufacturing

1. How to select the right large equipment supplier?

Evaluate suppliers based on qualifications, production capacity, delivery timelines, and after-sales service. Procurement management systems can expedite supplier screening through data analysis.2. How to control costs in large equipment procurement?

Use multi-round quotations, supplier competition, and long-term agreements. Cost analysis tools in procurement systems help monitor budgets effectively.

3. How to ensure procured equipment meets technical requirements?

Align with technical departments to define specifications upfront. 8Manage SRM’s demand management module centralizes technical requirements, ensuring procurement aligns with expectations.

Most popular

How IPD drives product R&D toward commercial success

Top procurement management systems to elevate your business in 2025

Are your project managers ready for AI?

Related articles

5 Key Innovations in Digital Procurement Software

2025-08-08

2025 Procurement Software: Top 10 SRM Systems Reviewed

2025-08-01

What is a PO and its role in enterprise procurement?

2025-08-01

8Manage SRM vs SAP vs YonBIP: Best enterprise procurement software

2025-06-13

Top 5 auction systems in procurement for boosting efficiency (2025)

2025-06-03

Previous Article >

5 Key Innovations in Digital Procurement Software

5 Key Innovations in Digital Procurement Software

Next Article >

2025 Procurement Software: Top 10 SRM Systems Reviewed

2025 Procurement Software: Top 10 SRM Systems Reviewed