-

The following is a more detailed look at what

can do in supplier scoring:

can do in supplier scoring:

Data-driven evaluation

can analyze historical data, including past performance, financial data, and compliance records, to assess supplier reliability and identify potential risks. This allows for a more comprehensive understanding of a supplier's strengths and weaknesses.

can analyze historical data, including past performance, financial data, and compliance records, to assess supplier reliability and identify potential risks. This allows for a more comprehensive understanding of a supplier's strengths and weaknesses.

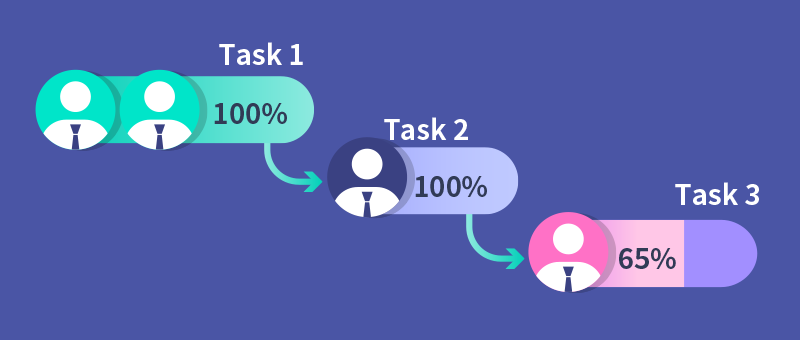

Automated scoring

can automate the process of scoring suppliers based on predefined criteria and performance indicators. This ensures consistency and fairness in the scoring process, minimizing human bias.

can automate the process of scoring suppliers based on predefined criteria and performance indicators. This ensures consistency and fairness in the scoring process, minimizing human bias.

Real-time insights

can provide real-time updates on supplier performance, allowing businesses to make informed decisions about contracts, renewals, and supplier relationships. This helps organizations stay ahead of potential issues and proactively address them.

can provide real-time updates on supplier performance, allowing businesses to make informed decisions about contracts, renewals, and supplier relationships. This helps organizations stay ahead of potential issues and proactively address them.

Risk assessment

can identify and assess risks associated with different suppliers, helping businesses prioritize their risk management efforts. This includes evaluating risks related to a supplier's capacity to meet contract terms and potential disruptions in the supply chain.

can identify and assess risks associated with different suppliers, helping businesses prioritize their risk management efforts. This includes evaluating risks related to a supplier's capacity to meet contract terms and potential disruptions in the supply chain.

Improved decision-making

By providing data-driven insights and automated scoring, AI helps procurement teams make more informed and efficient decisions about supplier selection and management. This leads to better overall supply chain performance and reduced costs.

Continuous improvement

can learn from past data and continuously improve their scoring models, ensuring that they remain accurate and relevant over time. This allows businesses to adapt to changing market conditions and evolving supplier relationships.

can learn from past data and continuously improve their scoring models, ensuring that they remain accurate and relevant over time. This allows businesses to adapt to changing market conditions and evolving supplier relationships.

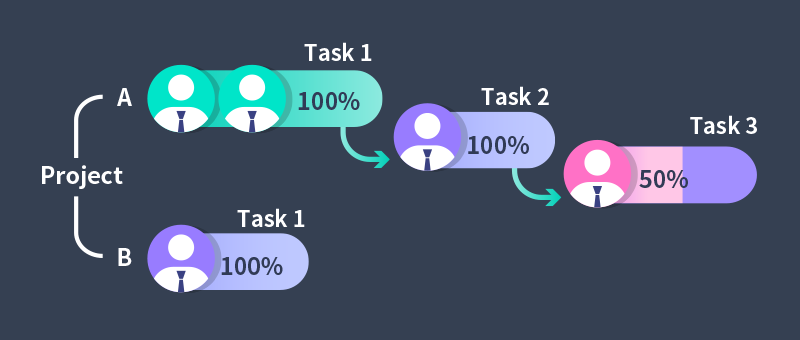

Supplier ranking and prioritization

can rank suppliers based on their value to the organization, helping businesses prioritize their partnerships and focus on the most critical suppliers. This allows for a more strategic approach to supplier relationship management.

can rank suppliers based on their value to the organization, helping businesses prioritize their partnerships and focus on the most critical suppliers. This allows for a more strategic approach to supplier relationship management.

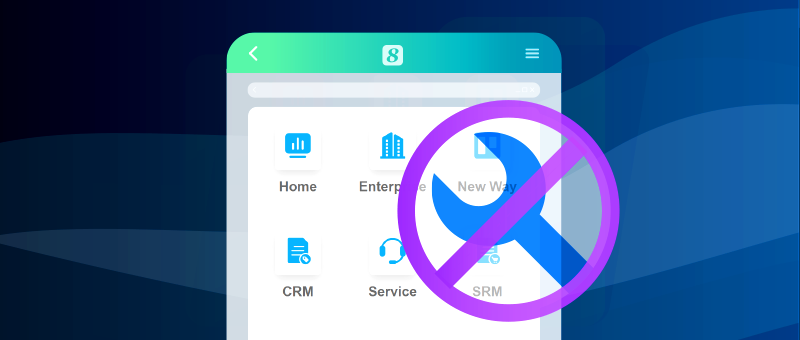

FLEXIBILITY

For teams

For industries

Workflows

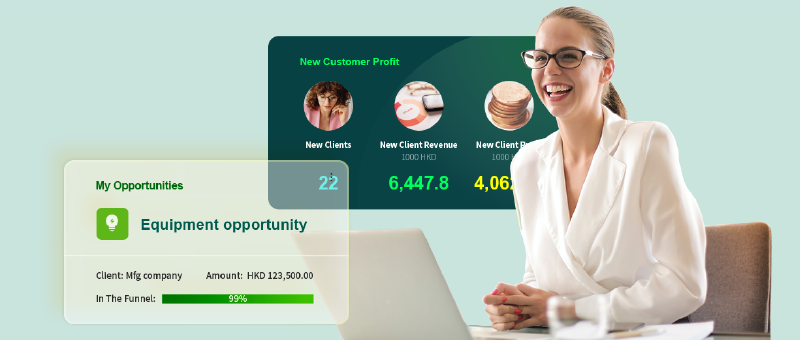

Sales

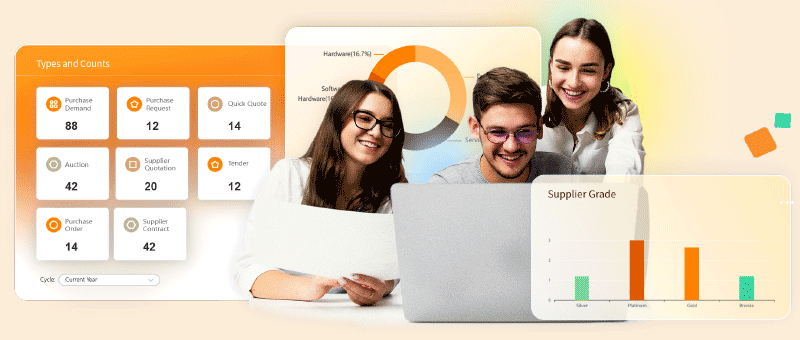

Procurement

Service

Supply chain

Project management

IT

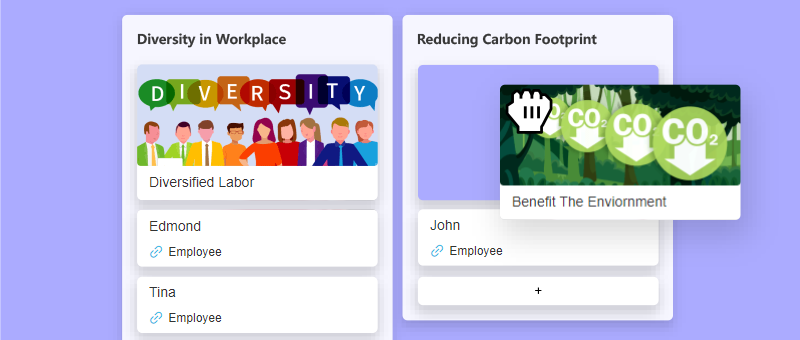

HR

Finance

Operations

Enterprise-wide

Airlines

Construction

Energy

Financial Service

Health Care

Professional service

Property development & management

Software/IT

Sales management

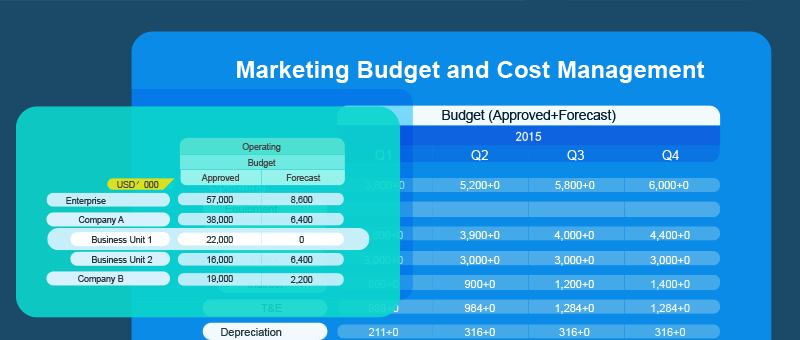

Cost management

Procurement

Project management

Outsourcing

Service management

Human resource management

Document management

AREAS

SRM ROADMAP

PPM ROADMAP

SRM ROADMAP

PPM ROADMAP

AREAS

FLEXIBILITY

home

solutions

price

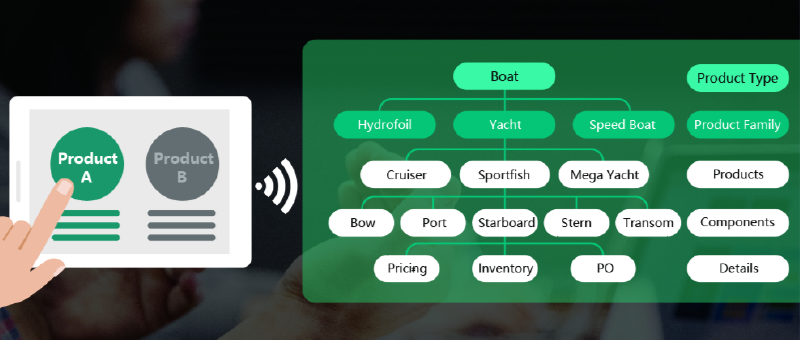

Supplier Scoring

can significantly enhance supplier scoring by automating data analysis, providing unbiased assessments, and offering real-time insights for improved decision-making in supplier selection and management.

can significantly enhance supplier scoring by automating data analysis, providing unbiased assessments, and offering real-time insights for improved decision-making in supplier selection and management.

can analyze vast datasets to evaluate suppliers based on various factors like performance, pricing, compliance, and innovation. This leads to more data-driven and objective assessments, helping procurement teams choose the best partners for their needs.

can analyze vast datasets to evaluate suppliers based on various factors like performance, pricing, compliance, and innovation. This leads to more data-driven and objective assessments, helping procurement teams choose the best partners for their needs.

Data-driven evaluation

Automatic scoring

Real-time insights

Risk assessment